Our expertise in product design and manufacture allows us to solve the challenges of turning a cproduct concept , new innovative product into a marketable product. Yenlik Kalip offers solutions when a product is not designed with manufacturing in mind. We take the time to understand the purpose of the product, its application and performance, the potential market, use and viability.

Plastic Moulding Solutions

At Yenlik Kalip, we offer an in-house service for new design, drawing modifications and product design development. Our engineers are trained in using 3D CAD software and are experienced in multiple disciplines for a variety of industriesServices We Provide

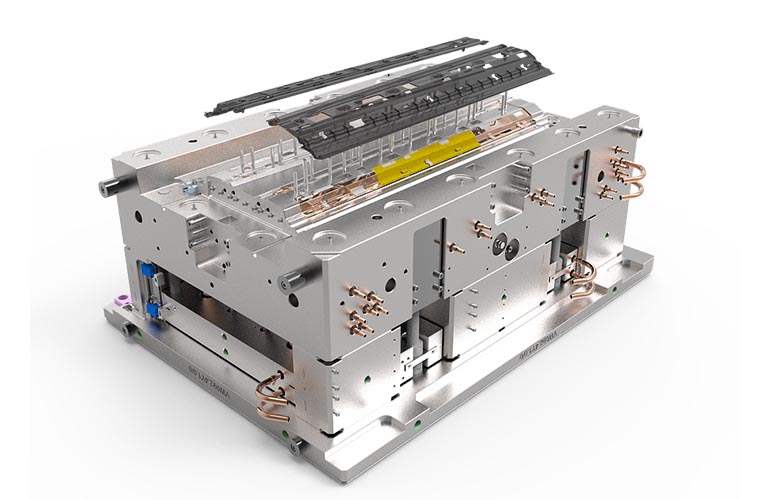

At Yenlik Kalip, we offer rapid injection moulding with quick turnaround times that will help reduce design risks and limit overall production costs. We have the capability to begin the process as quickly as possible, enabling us to produce rapid prototypes and end-use production parts. Not to mention, our tooling selection come with a lifetime guarantee and we stock hundreds of thermoplastic resins and liquid silicone rubber materials.

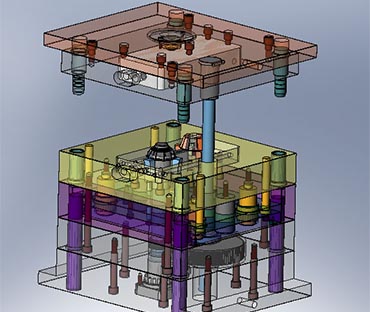

3D CAD

Computer Aided Manufacturing (CAM)

Analysing

Material

Selection

Our professionsl & experienced team can support

you through all project phases

-

Product Concept

Let us know more about your produt that you need to manufacture.

-

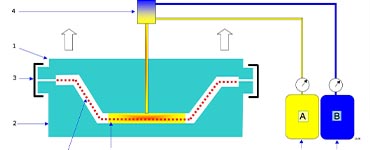

Material Research

We then do our research to choose the best materials and techniques that best fit your mould.

-

Injection Mould Design

Our lastest technologies are used to develop the required injection mould.

Our Business Goal

100%

customer satisfaction

Customers satisfaction is # 1 priority .

Benefits of our Plastic Injection Moulding:

- 1. Plastic Injection Moulding size capability from less than a gram up to over 6kg.

- 2. All materials selected to fit with customer needs.

- 3. 24 Hour maintenance and support to ensure cusomter satisfaction.

Our years of industry experience enable us to take an idea and turn it into a practical working model. We tailor our service to the specific needs of each of our customers, always trying to find the most appropriate solution to their individual needs.